|

RAPIDCHANGE ATC Bringing Automatic Tool Changing to Small Shop CNC Routers (Original unedited version.) Years ago

I wrote some articles for Woodshop News. At

the time I was running my curved moulding

business and enjoyed this diversion at the end of my work day. The first of those

articles was a review of

the newly introduced SawStop table saw.

I happened to be returning to Connecticut from IWF

in Atlanta on the

same flight as A.J. Hamler who was the editor of Woodshop News. Our conversation soon

turned to the SawStop

and the pending first shipment arriving in the US.

Since I had just ordered one I suggested that

I might write the magazine’s review.

Mr.

Hamler agreed and thus began my Woodshop News writing career. The

review of the SawStop was unquestionably favorable.

I was a big fan of the technology from the

first moment I saw it in action with a sliding hot dog.

When it turned out the saw was as

extraordinarily well engineered and designed as it was a giant leap

forward in

safety, it became easy to put together a positive review. (SawStop

review .....June 2005) Now, over

20 years later, something else quite different has

come along. While

this product isn’t

going to change the woodshop and construction worlds the way the

SawStop did, I

believe it will have a big impact on many small shop CNC router owners. RAPIDCHANGE

ATC Automatic

tool changing is somewhat of a holy grail in the light

to medium duty CNC router market.

Adding

an air activated ATC system to a CNC purchase is expensive. An ATC spindle, tool

holders, tool rack and

air drying system must all be added to the base router price. This means $10,000 or more

for a name brand

setup, or perhaps half to a third of that for a Chinese clone version. Either way it is a

disproportionately large amount

in relation to the base cost of an economical class CNC router. In my

retirement shop I have a 20 year old 4x8 CNC that I

purchased used and to which I did all the appropriate improvements and

upgrades.

As it sat I

had a pretty sharp

system. But what I didn’t have was

an automatic tool

changer. I had been

looking for a long

time for a good condition used name brand spindle for the heart of the

system but

never pulled the trigger for one reason or another.

I even considered going new with the Asian

import clone spindles but still held back. With

all the required accoutrements beyond the

spindle purchase it just seemed a disproportionate investment in

relation to

the overall value of my old machine. Then

one day while doing yet another online

search for ATC opportunities I stumbled on the Rapidchange ATC (patent

pending).

After

visiting the website (www.rapidchangeatc.com),

watching some

videos and reading some online reviews I emailed the company and

quickly got a

call back from Don Greilick. Don

is the person

behind this mechanical tool changer and a bunch of fun to talk with on

the

phone. He has a

strong background in

both the arts and engineering and along with his computer code savvy

son

developed the Rapidchange ATC. This tool

change system, at well under $1000 all in for even

the largest and most sophisticated of the options available, is a game

changer. And that

is what Don means it

to be. An

affordable automatic tool

changing system for the non-industrial classes of CNC routers. It is available with or

without a retracting

dust cover and in 4 to 8 slot variations with the possibility of more

tool

slots on a custom order basis. The

concept for this system is actually a fairly simple.

Your

spindle runs in forward to load a collet/nut assembly with your

pre-loaded

router bit, and in reverse to remove it. This

assembly is sitting in one of the tool slots

in the rack which Don refers to as the “magazine”.

The

spindle is typically set to run between 700 and 1000 rpm during loading

and

somewhat higher for unloading. After

loading the bit assembly and giving an initial amount of locking torque

to the

collet nut, the Z-axis will raise about ˝” and while still spinning

lower again

into the tool slot to “tap” the grab ring to provide a secondary torque

down of

the nut. On each

tap the rotational

force as the spindle stops creates the torque needed to tighten the nut. This

works because each location in the tool magazine has a spring-loaded

lock ring designed to grab the collet nut the same way as your wrench

would. This is the

case whether your

collet nuts have milled slots for the wrench to grab or are simply hex

shaped. The spindle

rpm is set low

enough so that the downward motion of the Z-axis can drive the nut onto

the

grab pins in the lock ring while being fast enough to create the needed

torque

to tighten the nut. Depending

upon the

collet design, that is ER11, ER16, ER20 and others, two or three total

“taps”

of the tightening procedure will do the job. There are

various length tool magazines available so you can

size the system to your needs. The

magazines

are specifically designed to accommodate each of the different

collet/nut types. Don

has most of the major styles already

covered and is adding to the repertoire on a regular basis. In fact, the SYOZ-20 setup

on my Perske 5hp

spindle was a new one for him. TECHNICAL

DEVELOPMENT The idea

for the Rapidchange ATC occurred to Don in 2022

while cutting some material on his own CNC router.

He was captivated by the idea and with a bit

of experimenting came up with his first prototype magazine that very

day. As is always

the case when developing a new

device some parts worked right off and some needed attention. Over the next 6 months he

worked through

these details and was then ready to show the Rapidchange ATC to the

world. To do so he

created a video post on the

social media platform Discord (www.discord.com)

and literally within minutes he had people asking for more information. This led to his widely

viewed YouTube channel

and subsequently to sales to date to hundreds of users around the

world. While the

idea of just spinning a collet nut up onto a

router spindle seems like it would be pretty simple those months of

product

development were actually pretty intense.

There were a number of theoretical details that were

simple enough in

concept but a bit more complicated to actually work out. First and

most obvious was the issue of running a router

spindle in reverse for unloading.

This

can be done with most Variable Frequency Drives (VFDs) that run high

speed

spindles but not all. Then

of course

many lower cost CNC routers incorporate hand held routers not capable

of

running backwards. This

means that not

all existing CNC routers can take a Rapidchange ATC without a spindle

upgrade. However, a

2 to 3 hp spindle with matching

VFD can now be bought as an import for under $500.

So even if a CNC owner has to add that to the

cost of the Rapidchange ATC the overall cost remains a small fraction

of installing

a traditional air driven ATC system. Next up

was probably the biggest question Don faced.

What about torque?

Could the slow speed loading rpm create

enough rotational torque to solidly lock the collet nut to the spindle

shaft? Don will

admit he was initially skeptical.

However, experimentation on the prototype showed

that with some tweaking to the process, and with multiple “taps” using

the

spindles rotational force to bump the nut tighter as the spindle stops,

he

could get the nuts as secure as with a set of collet wrenches. But this

type of loading process where the spindle is

brought to a momentary stall brings up the question of possible damage

to the

spindle. To be

honest I haven’t found

any research in this area nor have my inquiries to people who sell and

service

CNC spindles provided any data. However

with hundreds of Rapidchange ATC units in service Don tells me there

have been

no reports of spindle problems during the first year plus of sales. Once the

torque issue was sorted out the last major question

was could the collet nut be made to consistently spin up onto the

spindle

without cross threading. Further,

even

if that could be done, what would happen if for some reason the nut did

bind on

the initial grab. That

could be a major

problem. You

wouldn’t want a partially

mounted collet/bit assembly running at high rpm while not being

properly seated

and tightened in place. To handle

this Don came up with a method to reduce the chance

of cross threading along with also adding safety features that address

the scenario

if it should occur. On this

issue of cross threading I will say that a new owner

shouldn’t be surprised if it happens on the first tool pickups after

initial setup. There

are some very precise alignment steps

that need to be completed in order for the tool changes to work

seamlessly. Even if

the install is being guided by a

wizard (for now only available on UCCNC control software) your first

run

through might not end up with the precision settings needed to make

this work. For

other control software packages that

don’t yet have setup wizards the process is a bit more rigorous but

doable. Don

continues to work to make

the wizards available in more CNC control packages. Doing

the installation To do the

setup in a way that will lead to repeated successful

tool pickups and drop-offs from all the tool positions you first need

to get

the magazine exactly parallel to one of your router’s axes. Getting this done is

assisted by a provided

CAD drawing of the mounting hole locations.

That drawing can be imported into a CAD program so

that the router can precisely

drill the mounting holes for you. After the

magazine is mounted to your CNC the exact location

of tool holder position #1 needs to be established.

Having done this myself I will say that it

requires a high degree of accuracy as all the other tool positions work

off of

#1. If the recorded

position is off by even

a few hundredths of an inch clean tool pickups will not happen. However doing this is

actually not all that

difficult. I’ve

done it with and without

the UCCNC wizard and once I got a feel for the process I was doing it

in a minute

or two. Plus of

course CNC routers are

high precision machines so repeatability once you get your Tool #1

location is

pretty much assured. If you

have gotten your positioning co-ordinates properly

set, and your tool magazine is level and parallel to the bottom face of

the

spindle shaft, you will get clean pickups.

I had some initial issues here but was able to

narrow them down to a few

small out of alignment factors. My

final

check was to mount a ˝” rod in the router and examine the squareness to

my

spoil board. To my

surprise I found it

was off by about .03” over the 5” long rod.

This

was enough to give me some

inaccuracy during tool pickup. This was fairly easily

corrected by loosening

my Z-axis mounting plate bolts and tweaking the spindle’s vertical

orientation. Lastly,

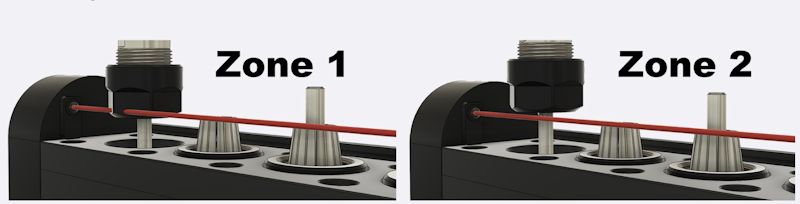

in order to assure that a bit assembly has loaded

correctly there is an IR eye (on the retracting dust cover

model.....and soon

to be on the base model as well so visual confirmation is not required)

that

scans across the magazine after tool pickup.

If the collet nut has been threaded all the way up

and above the IR

transmitter level it will see the IR receiver on the other end of the

magazine

and an “all clear” signal will be sent to the software.

If the nut has not spun all the way up onto

the spindle threads it will be blocking the eye’s line of sight to the

receiver. In this

case the software will know that you

don’t have a fully threaded collet nut and the router will travel to a

convenient wrenching location so you can fix the problem.

The only

other possible issue I know of with the Rapidchange

ATC would be bit slippage when sitting in the magazine.

Not all router bits are a tight fit when

inserted in a collet and thus depend upon tightening the nut for a

solid grab. As such

while loosely assembled in the magazine

the bit might slip downward in the collet. One

solution of many would be to put a dab of

hot melt glue on the butt end of the bits when putting them into the

collet. This should

be all it takes to prevent

slippage and shouldn’t cause any problem with high rpm spindle balance. Again

though, this would only be if a bit is slightly loose to start with. BIT

LENGTH MEASUREMENT Router

bits don’t end up in exactly the same spot in the

collet every time the nut is tightened.

Bit

creep as the nut is tightened or slippage in the magazine can change

the length

of a bit below the collet face.

Since

the bit/collet/nut assembly has been sitting free in the magazine it

needs to

be measured with each pickup. That means that while your

top of material

location will remain constant with bit changes, the bit length assigned

to each

tool needs to be updated with each tool pickup.

The end

slot in the tool magazine is set up to accommodate a

touch down plate (sold separately) instead of a router bit assembly if

that is

what a user wants. If

someone already

has a different style touch down plate available for permanent

mounting, or

simply wants that magazine slot for another router bit, they can mount

an

external touch down plate somewhere near the magazine.

Either way the M6 tool change macro supplied

with the Rapidchange ATC accommodates the various setups via the

software

interface. On my CNC

I even added a retracting platform that the

Rapidchange ATC and external touch down plate are mounted upon. This

is so the ATC can extend over the work surface where my spindle can

reach it when

needed and retract out of the way on my X-high side of the table when

not in

use. The

Rapidchange ATC software has an

option to run a pre and/or post tool change custom macro which I use to

activate the extending platform’s air cylinders at the appropriate time. USING

THE RAPIDCHANGE ATC The

Rapidchange ATC is used just as any other automatic tool

changing system. You

set your CAM

software to the tool changer post processor for your machine and load

up the

tool magazine in the software just as you would with an air activated

ATC

spindle system. You

will then need to

make sure your particular post processor places an “M6” in the tool

number line

in the G-code (“M6 T01” for example) as that is required to activate

the tool

change process. If

the “M6” is not there

it is typically a small change in the post processor and as in my case

with

Enroute, the CAM software company might do it in a matter of a few

minutes at a

minimal charge. Once the

correctly generated G-code is being created then just

make sure the needed router bits are installed in the magazine

positions to

match the CAM software. When

a tool is

called up in the G-code the router will go to the correct slot, pick up

the tool

assembly, measure the bit and then travel to your cut start point. As long as you’ve already

touched down to the

top of your material each tool will know exactly where that is.

This

photo sequence shows the bit loading and measuring

steps as performed on B.H Davis’s retracting platform Rapidchange ATC. WHAT’S

TO COME Don isn’t

resting on his laurels with the Rapidchange

ATC. In addition to

bringing in more CNC

controls with matching wizards he’s working on a turret magazine,

looking at bringing

the system to milling machines and working with some smaller CNC

manufacturers

to include the Rapidchange ATC right from the factory. So what

do I think of the Rapidchange ATC?

I imagine it’s pretty obvious that I am

significantly impressed. I

purchased my

first CNC router back in the late 1990’s.

It was a used 5x10, 2-head machine.

I was brand new to CAD, CAM and MS-DOS control

software (yes, MS-DOS)

and the router was the first one I’d actually ever seen in person. Yet, within a matter of

months I knew I

wanted to add an automatic tool changer.

I did the

research, bought the parts, found a deal on a

spindle, purchased an air dryer and upgraded the CNC control hardware

from

mechanical to OPTO-Isolation relays.

It

was a whole lot of education, time and money but in the end worth all

of it. When it ran

for the first time I sat and

watched it changing tools for an hour with a boyish grin on my face. Believe me when I say that

adding the

Rapidchange ATC was just as successful as that first home made

system.......and

a whole lot easier. When

it ran for the

first time I sat and watched it with that same silly grin. BH Davis For

more information Rapidchange

ATC website:

https://rapidchangeatc.com/ Early

Youtube video describing the development:

https://www.youtube.com/watch?v=RR8noEJYduA Early

Rapidchange ATC without using reverse:

https://www.youtube.com/watch?v=hXpaJrEpSnE BH Davis

setup with extending table: https://www.youtube.com/watch?v=281kVTISxws Discord

channel: https://discord.com/channels/1077383334080032898/1077383334080032901

|